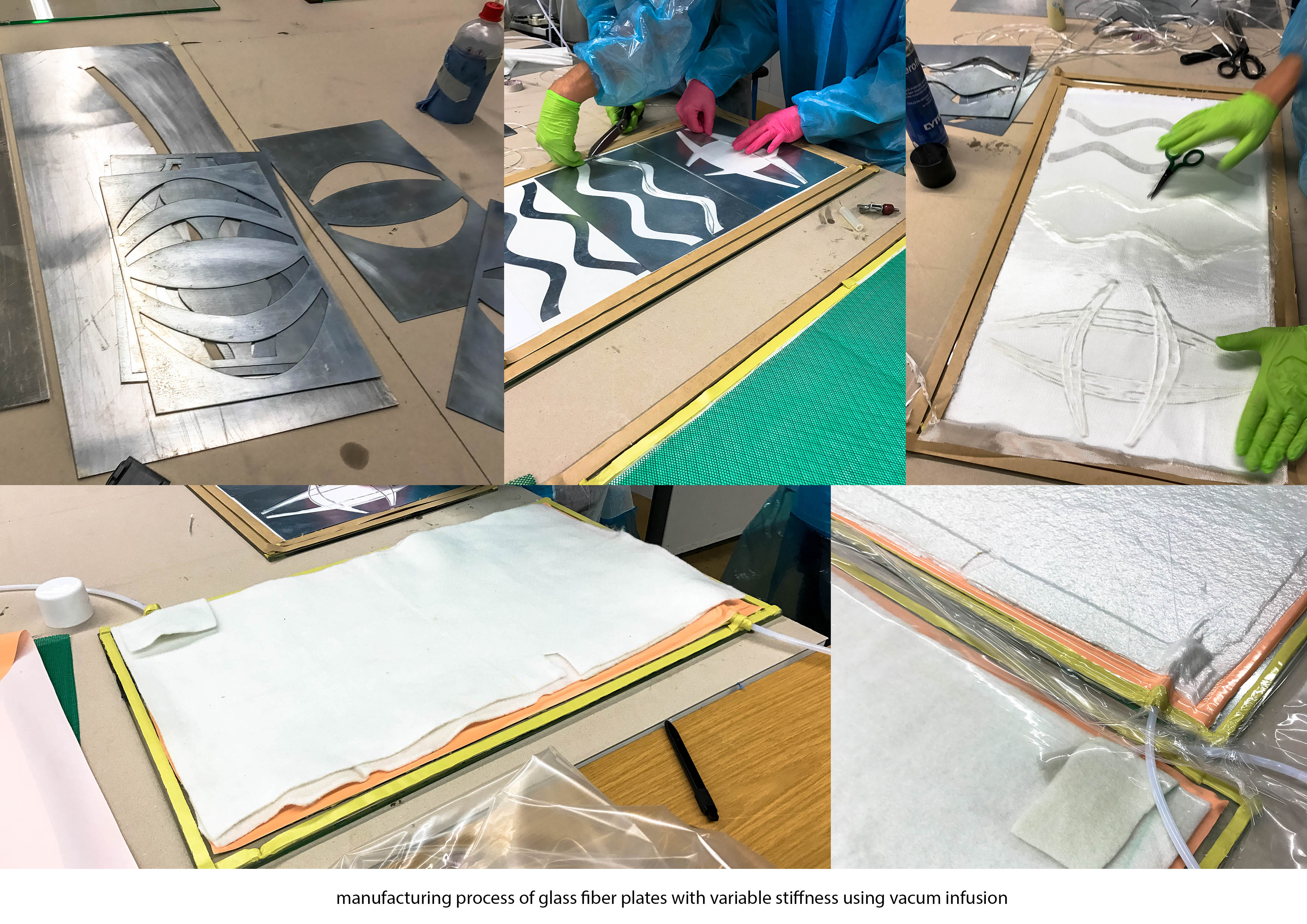

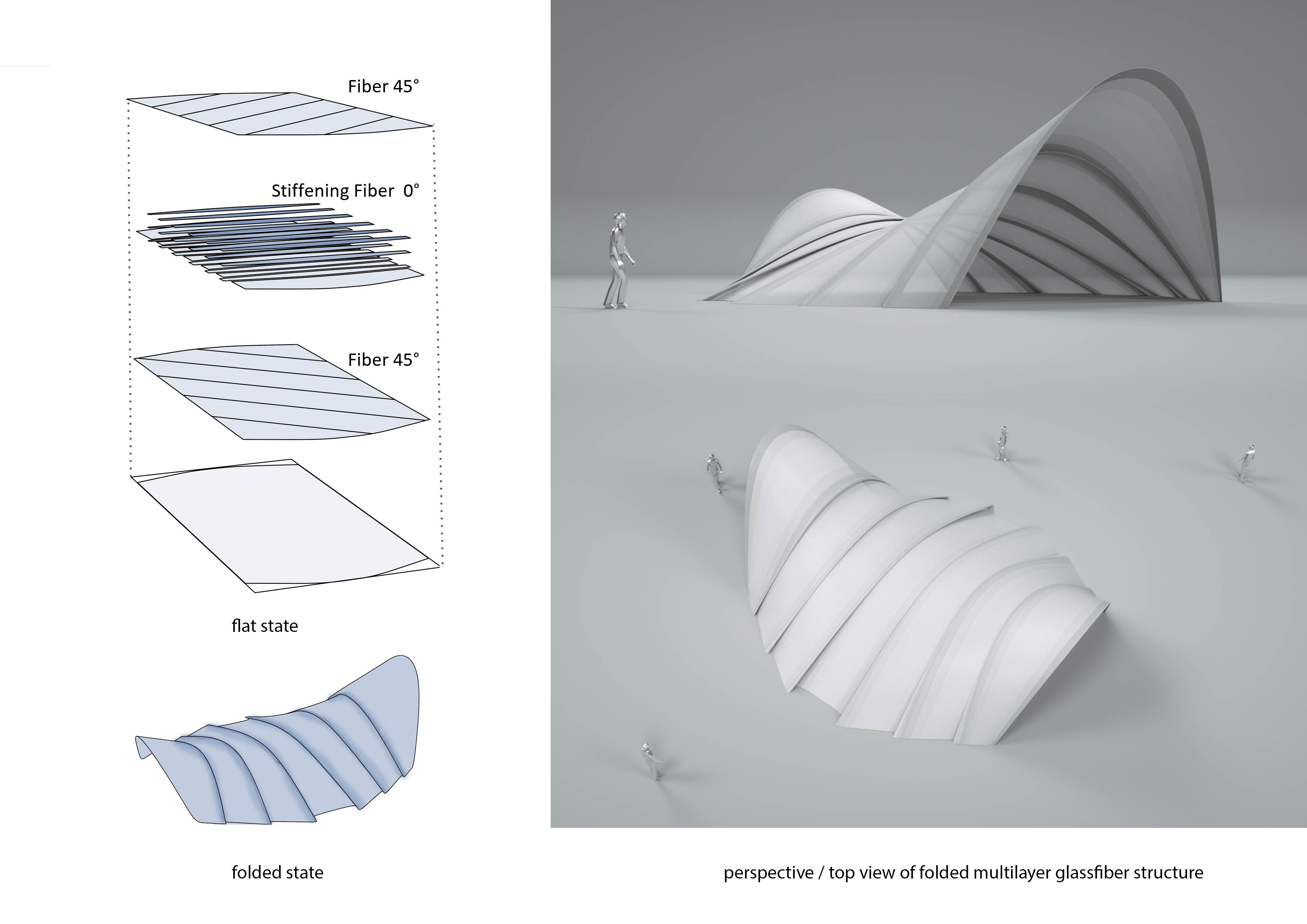

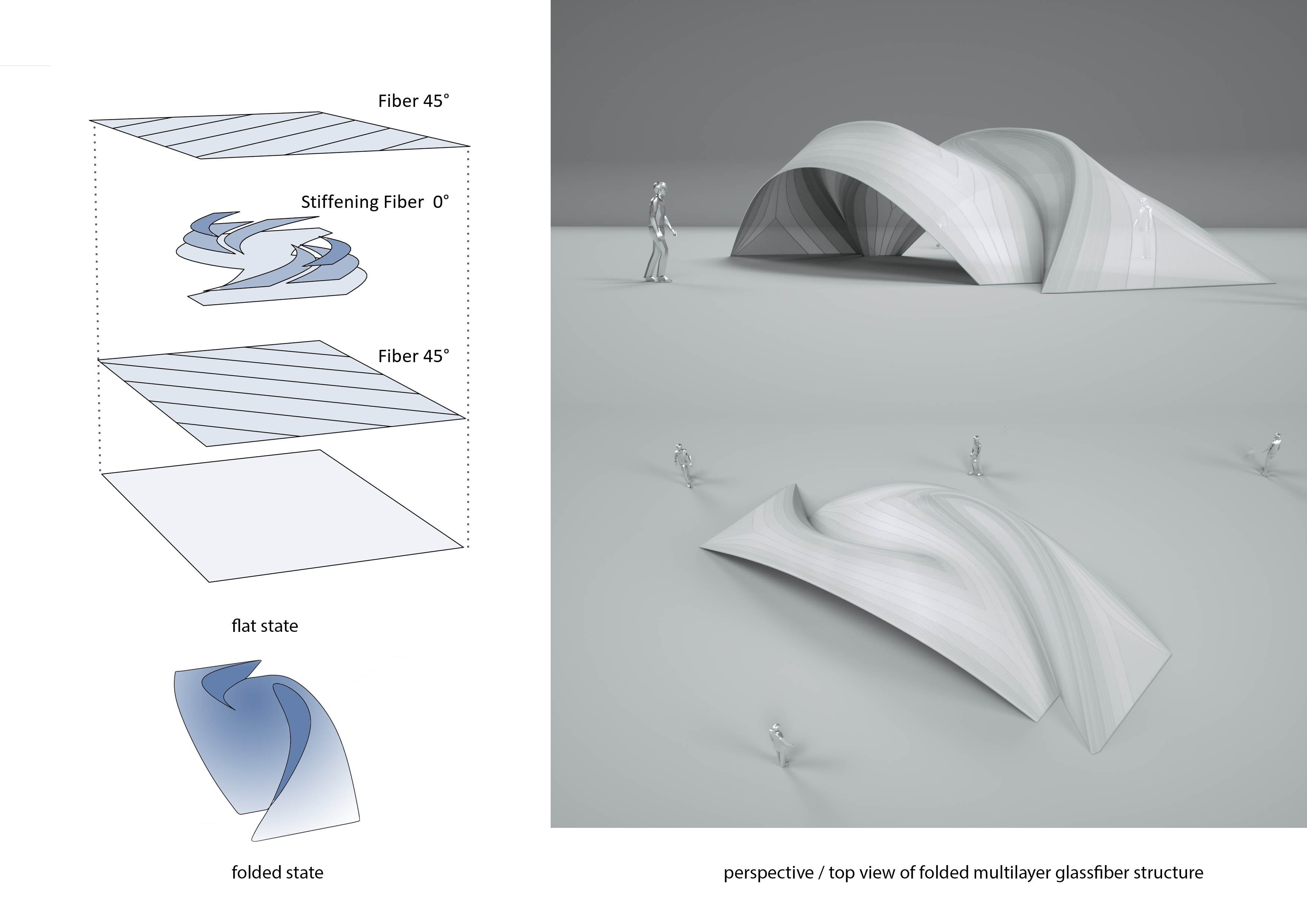

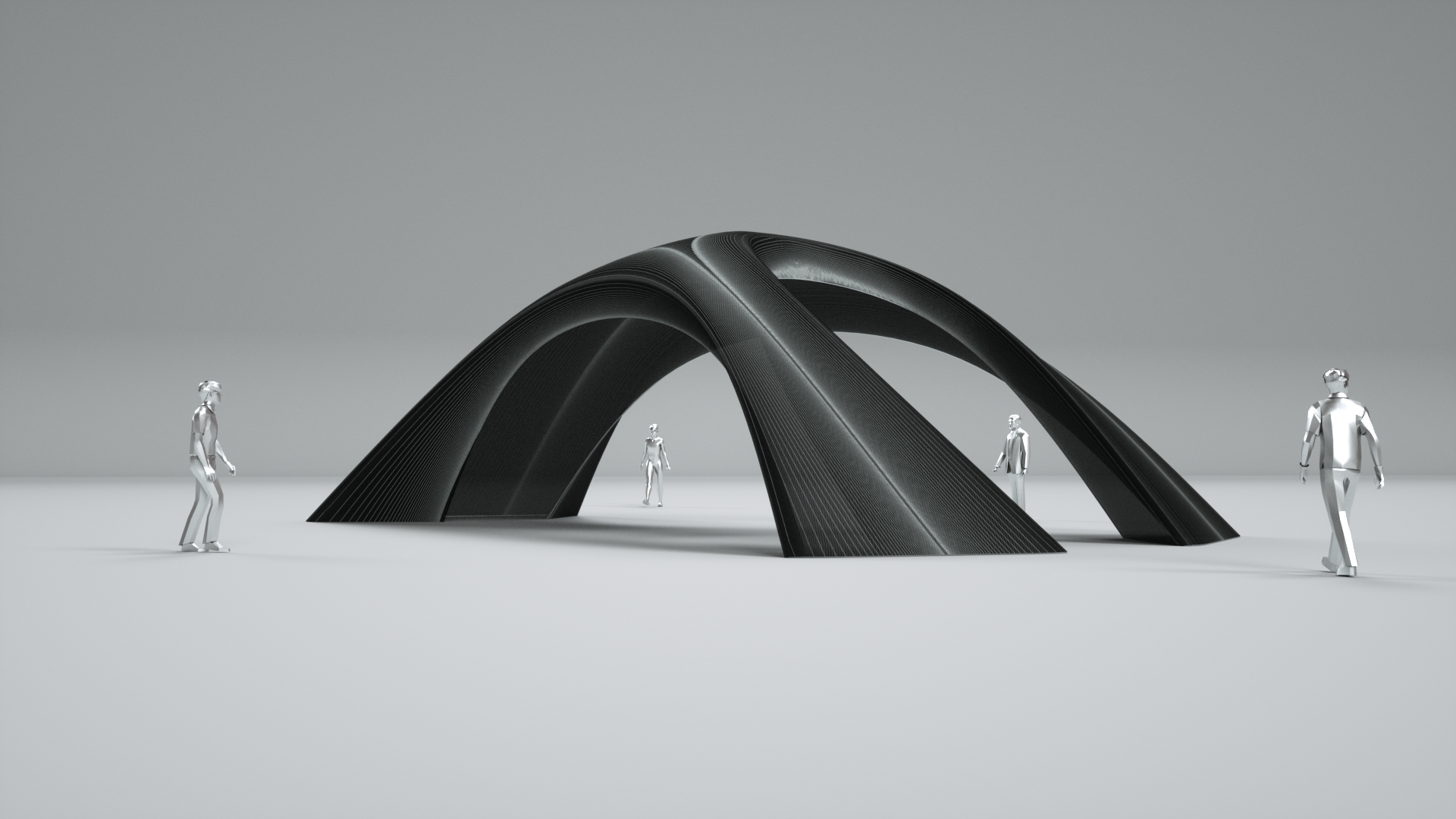

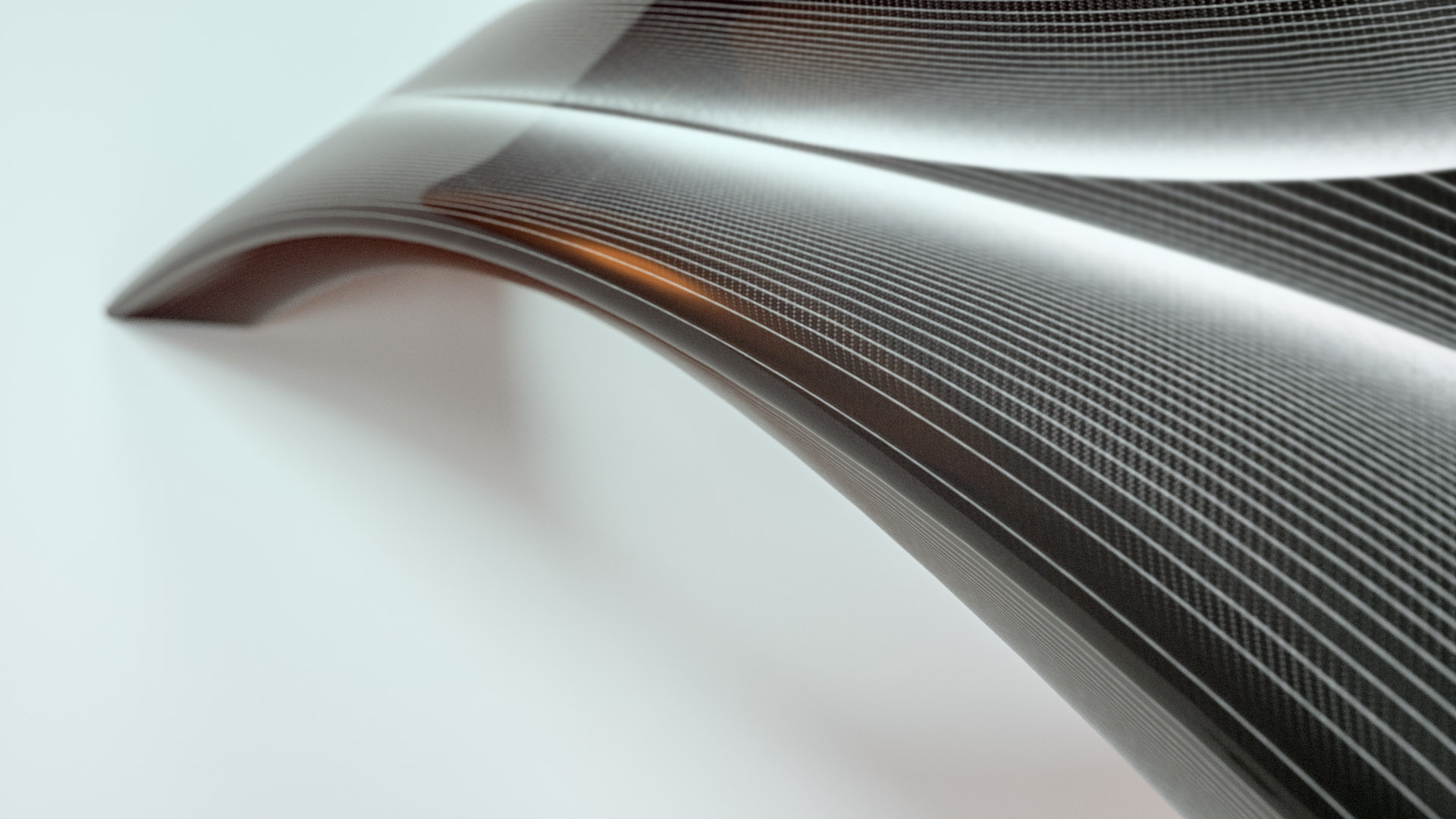

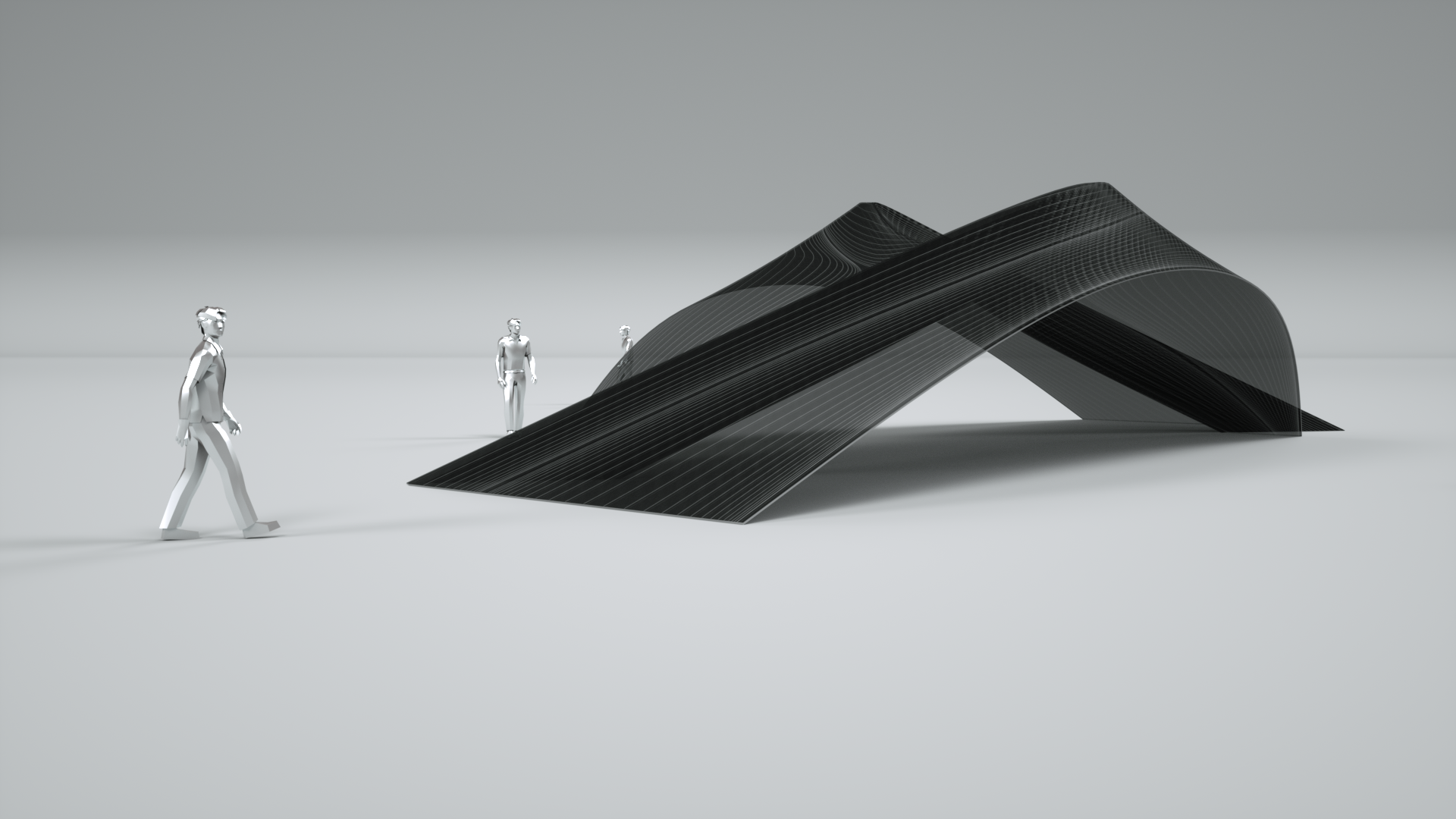

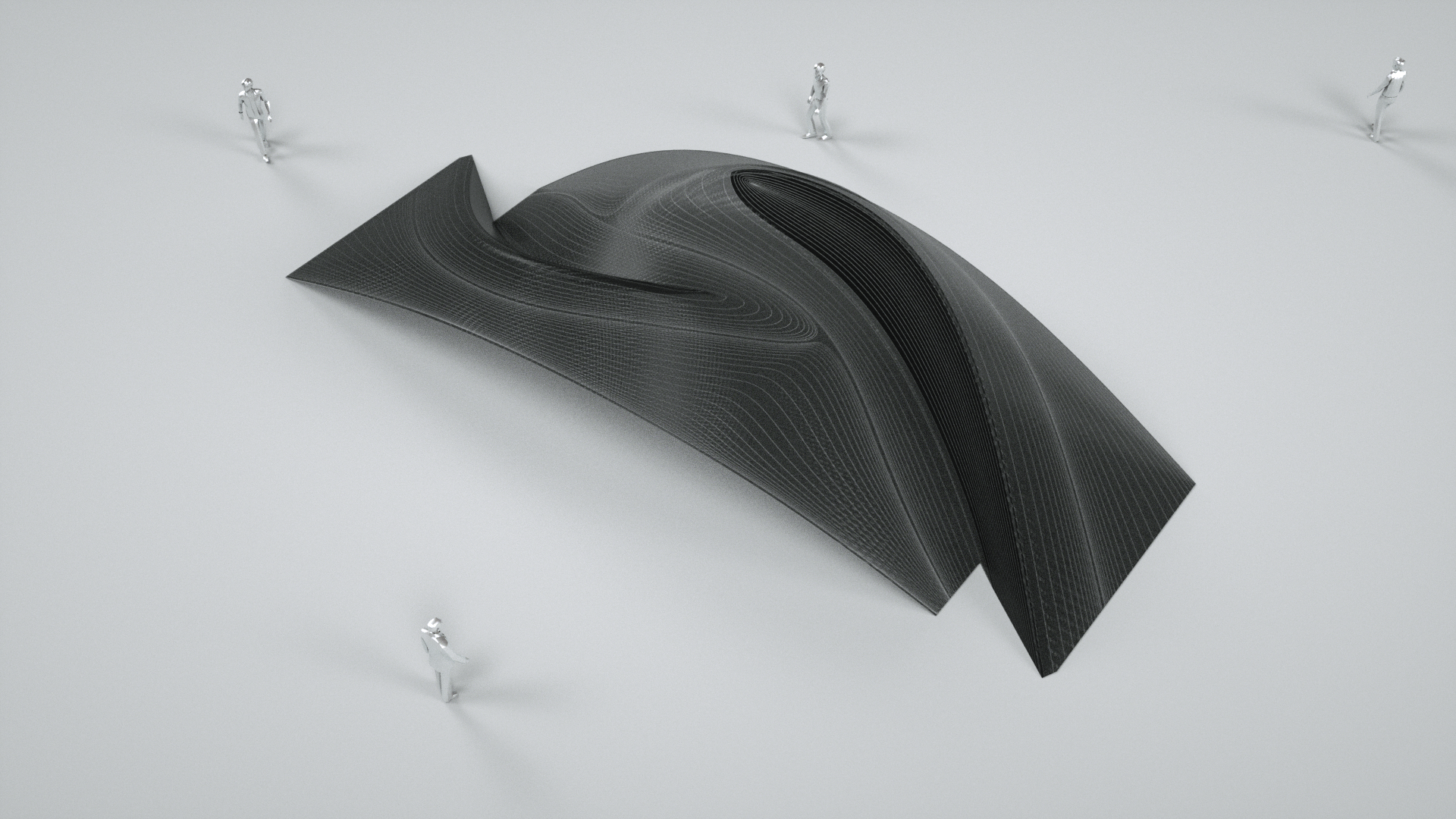

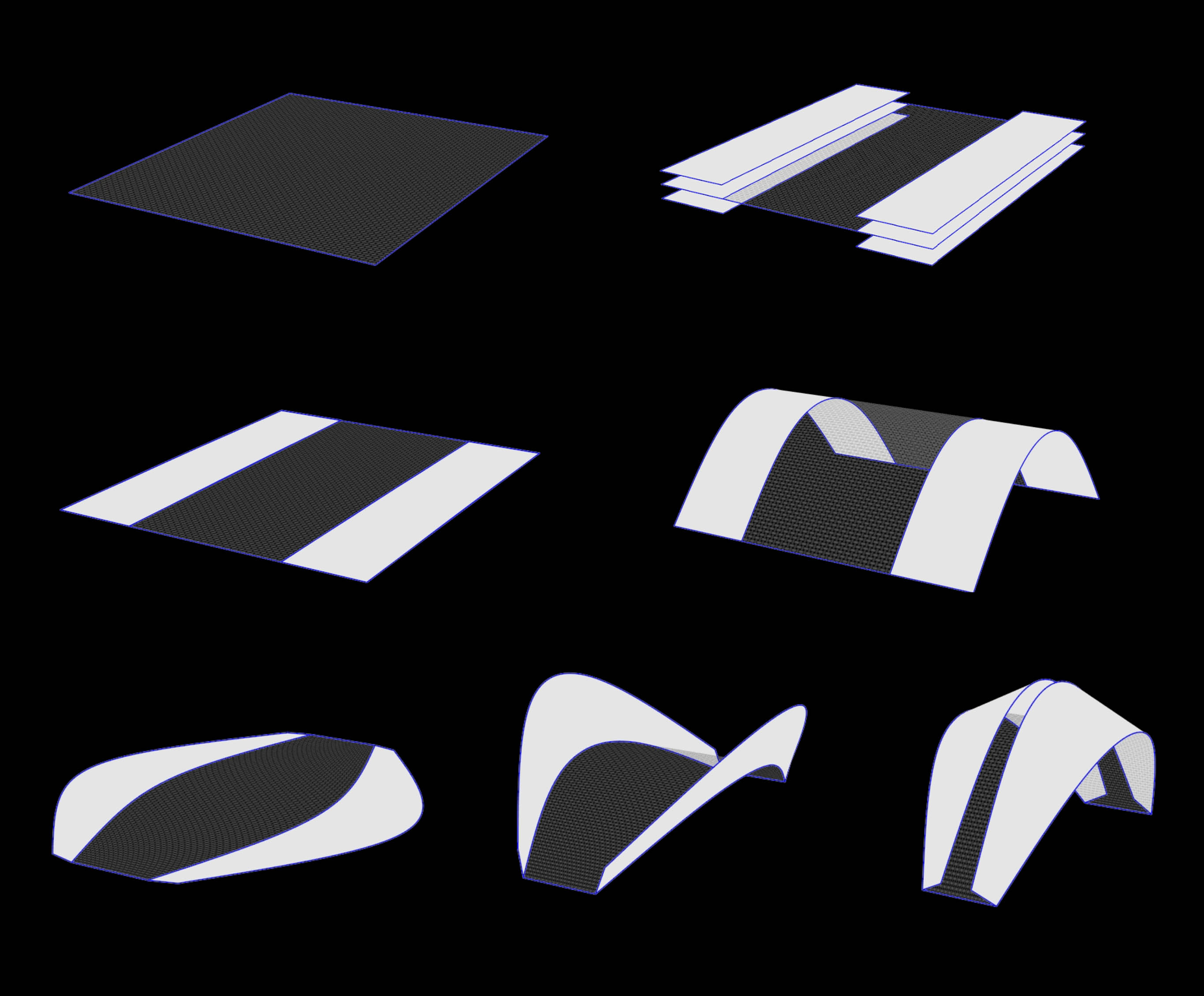

The project Hybrid Materiality explores the potential in implementing material gradients in plate structures using available manufacturing techniques. The compiled research aims to enable the fabrication of highly complex and differentiated three dimensional structures out of flat sheet materials. The system could be transported as a flat pack and through applying force onsite unfold itself into a final shape. The Research builds up on the current Investigations at ICD and ITKE into custom Robotic manufacturing processes and highly complex folding and fibre composite structures. Introducing material gradients and geometries inspired by curved folding structures the system has a lot of potential still left to be uncovered. To further investigate it is proposed to broaden the investigation into full scale real world material testing using automated manufacturing processes. Secondly, advanced computer simulation of bending stiffness of the plates informed by the material testing could be used to quickly iterate and advance the design system.

.University of Stuttgart, ITECH, with Brad Elsbury, Elaine Bonavia and Samuel Leder, 2017

ITKE Prof. Jan Knippers, Anja Mader, Evy Slabbinck / ICD Prof. Achim Menges, Lauren Vasey, Daniel Reist